we 3D scan anything and everything

At sample & hold we are asked to 3D scan a wide range of objects which are then used as the building blocks for design projects. If you have a model, a full size prototype, or even just a shape that you need to digitise to be the basis of your object. If you have an existing product that you need 3D scanned for a new manufacturing process. If you have tooling that needs to be replicated to continue production. No matter what stage of the design process you are at we can help. Whether the next stage of your project is to alter the design, generate CAD data or go straight to production, we have the experience to advise on or manage downstream processes to ensure you get just what you need.

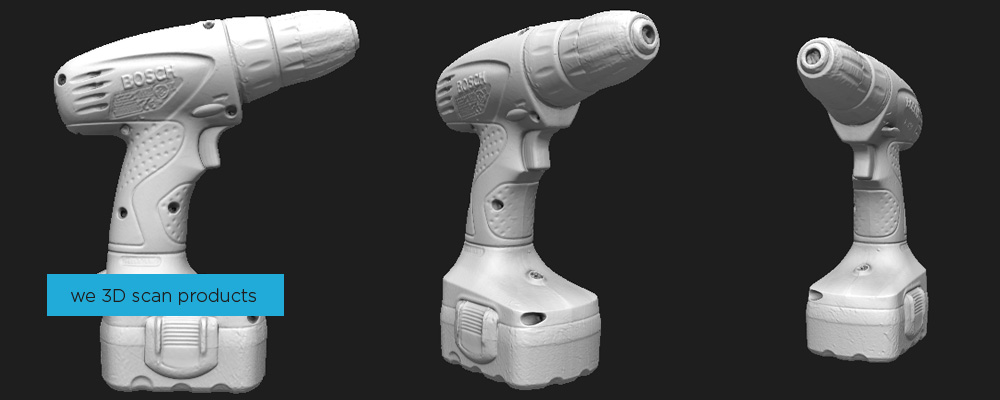

products

At sample & hold we are asked 3D scan existing products so that design modifications can be made, new products can be created to compliment the original, or perhaps the original tooling has degraded or needs upgrading. Our 3D scanners are accurate and can 3D scan complex shapes and tricky surfaces.

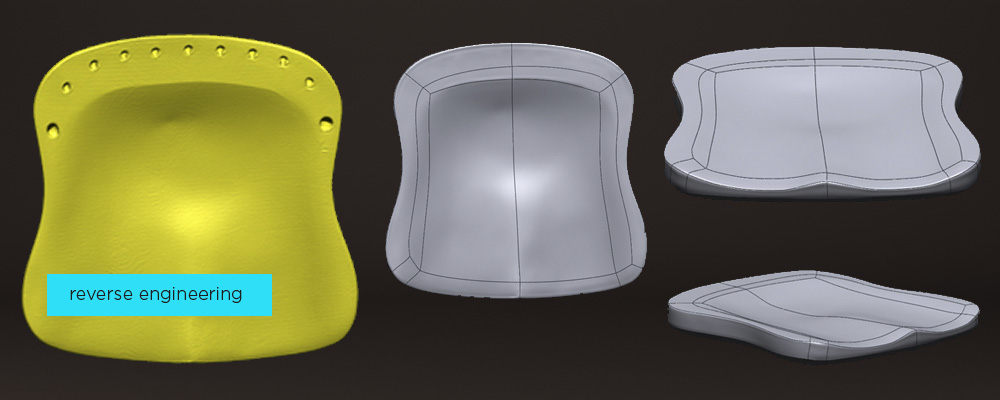

prototypes

Often a physical model is an more intuitive starting point for a design project than staring at CAD data on a screen - especially when sharing your thoughts with colleagues of clients. Once you are happy with your design we can quickly and accurately 3D scan your prototype model so that the project can continue in the digital realm.

“Absolute accuracy of the surface deformation was needed to assess the light redirection and scattering properties of this façade cast glass sample. I was impressed by the quality of the final 3D model. This allowed a better understanding of the geometrical properties of the surface, that could not be obtained otherwise. sample & hold supplied the model with different degrees of resolution at no extra cost, and this has been extremely useful to set up and run the simulations and analyses without wasting time with post-processing and re-sampling. Thank you!”

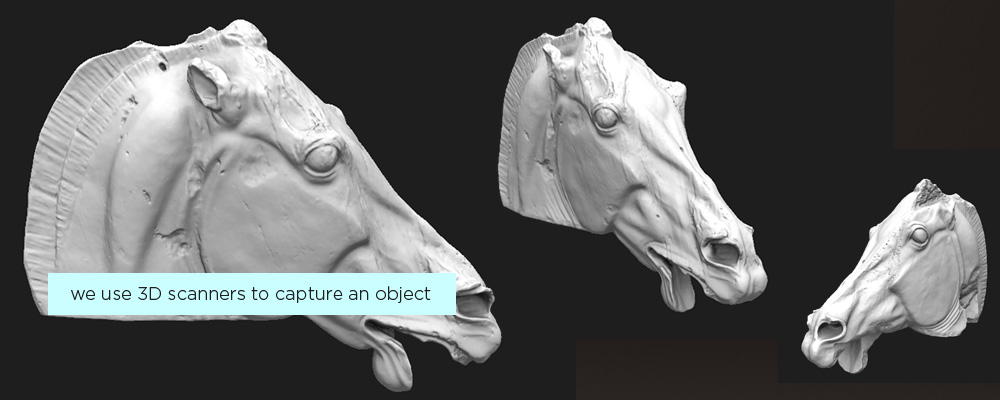

museum collections

Object collections are an important asset to any organisation and they often have hidden potential. sample & hold have the capability to unlock this potential by 3D digitising a collection for use as an exhibition tool, online gallery and for scientific, restoration and archival purposes. sample & hold use 3D scanners which are capable of capturing high resolution feature details in full colour - and the process is completely non-contact so delicate objects are not compromised in the capture process.

Our 3D scanning kit is fully portable and we have traveled all around the world 3D scanning historical objects, big and small, in a museum or out in the field, for commercial or research reasons.

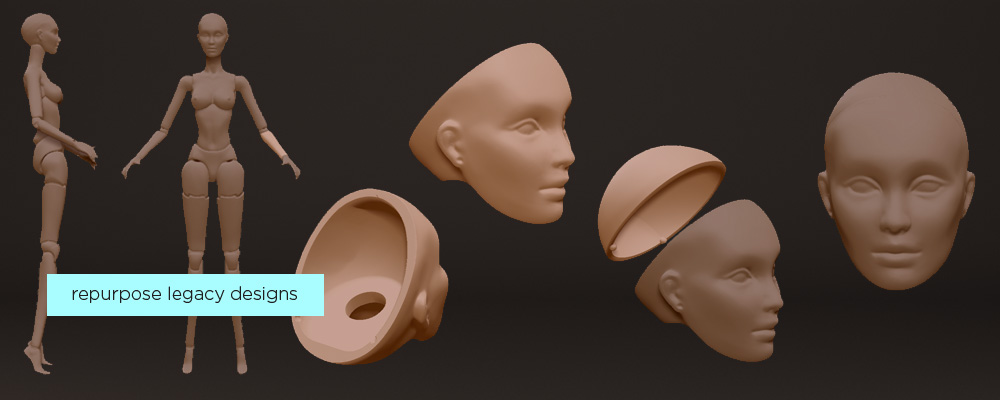

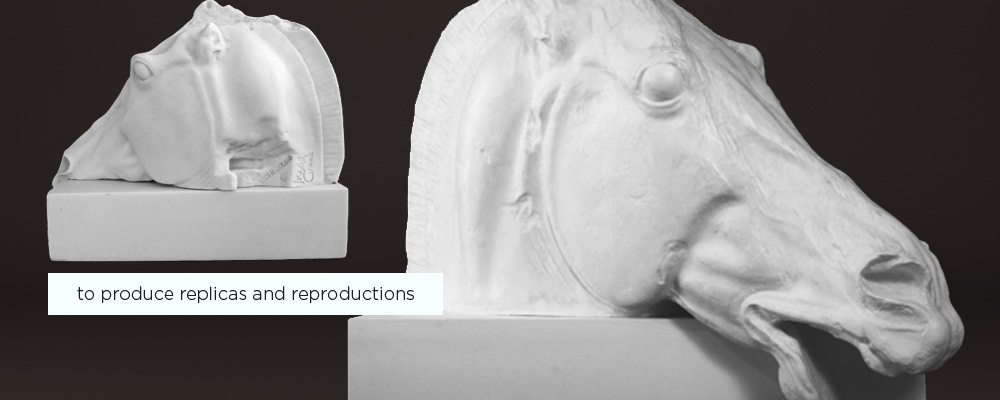

replicas

We have many years of experience using our 3D scanners to replicate objects. There are a number of reasons to use 3D scanners to reproduce museum objects, the two most obvious being the non-contact nature of 3D scanning and the ability to easily change the scale of the final reproduction. We can record your object in full 3D without having to touch it, in your museum or store, so no transport worries. Once the 3D model is in the computer we can change the scale of the object and prepare it for manufacture. We then use 3D printing or digital CNC machining to produce a master from which a mold can be made and the object cast in the desired material - ready for your shop, catalogue or educational department